Soldering Robots

![]()

The BEST source of QUICK Soldering Robots in India for mass electronic assembly manufacturing at competitive price.

![]()

Quick Automatic Soldering Robot / Automatic Soldering Machine increases production with less hands and ensures consistent soldering quality for each joint. Ideal for Automatic PCB soldering - spot & CNC. Available at best price in India. 100% after-sales service.

Quick Soldering Robots are automated machines designed to perform precise soldering tasks quickly and efficiently. These robots are equipped with advanced control systems and high-precision soldering tools, such as irons, tips, and dispensers, to perform various soldering applications

3-axis and 4-axis quick soldering robots are capable of moving in three or four directions, respectively, and can perform a wide range of soldering operations, including surface mount technology (SMT), through-hole technology (THT), and manual soldering. These robots are commonly used in electronics manufacturing, where precision, speed, and consistency are essential.

ome of the advantages of using quick soldering robots include increased productivity, improved solder quality, reduced labor costs, and a safer working environment. These robots are also highly customizable, and can be programmed to perform specific soldering tasks based on the requirements of the application.

Quick Soldering Robots are an excellent investment for businesses looking to streamline their soldering operations and improve their overall efficiency and productivity.

![]()

Single Axis Semi-auto Soldering Robot

Model: QUICK ET9181

The ET9181 is a Semi-Automatic Soldering Robot features Hot Iron, capable of delivering and maintaining a tip temperature with industry leading stability and accuracy. Automatic Feeder pull solder wire from the spool and also perforating the surface of the solder wire; to prevent solder balls. The 280 Watt Power Supply is capable of maintaining a temperature of up to 550°C.

- Specially designed for soldering cables, USB, connectors, aviation plugs, PCB, terminals and switches etc.

- Better option for replacing manual soldering stations and improving soldering efficiency.

- Concise appearance and sheet-metal structure.

- LCD screen, soldering time and wire feeding amount are adjustable.

- Stepper motor control, no need of compressed air.

- Easy programming.

- High frequency current heating, fast temperature recovery .

- Programmable for speed/time, feeding/interval etc.

- Suitable for use with a wide range of fixtures.

- Power Consumption

- Temperature Range

- Power Supply

- Temperature Stability

- Solder Wire Diameter

- Dimension

- Motor Range

- Soldering Time

- Weight Around

|

|

: 280W |

|

|

: 200-550°C |

|

|

: 220V |

|

|

: ±3°C (no load) |

|

|

: 0.8, 1.0, 1.2,1.6mm |

|

|

: 285X420X265mm |

|

|

: 80mm |

|

|

: 0.01-9.99s |

|

|

: 13Kg |

- 1-Axis Soldering Robot

- Soldering Tip

- Foot Switch

- Connecting Cables

- Instruction Manual

![]()

3-Axis Highly Reliable Soldering Robot

Model: ET9383E-BB1 / ET9483E-BB1

3-Axis Soldering Robots are robotic machines designed to perform precise and automated soldering tasks in a manufacturing or industrial setting. These robots are called 3-Axis because they can move in three dimensions: X, Y, and Z. This allows a greater flexibility and precision in the soldering process. These Soldering Robots increases production with less hand and ensures high quality persistent soldering quality for each joint.

These Soldering Robots can be programmed to perform specific soldering tasks, which help to increase efficiency and reduce the chance of errors. This automation can also help to reduce labor costs and increase overall productivity.

Overall, 3-Axis Soldering Robots are a valuable tool for any business that requires precise and consistent soldering. However, it’s important to carefully consider your specific needs and requirements before making a purchase to ensure that these robots are the right fit for your business.

- Motion Platform

E-Series Soldering Platform is of high speed & high accuracy with low noise, closed-loop control of Y-axis, no lost steps, strong load capacity, easy maintenance, rich I/O interfaces, support MES to read local data and expand operation use, two-hand start (optional), ESD safe - Heating Controller

Heating Controller uses high frequency eddy current heating for stable and reliable temperature, fast thermal recovery, RS-485 interface for real-time monitoring and to set parameters like temperature, solder feeding etc, alarm for abnormal temperature and solder shortage etc. - Soldering Pencil

High Power Soldering Pencil has front temperature sensor for quick sensing of solder joint temperature fluctuation and rapid thermal recovery. - Solder Feeder

Small size and high precision, controlled by precision stepper motor, the minimum solder feeding length can reach 0.1mm, solder shortage and block alarm function available. - Teaching Pendant

Teaching Pendant, supports array and group functions, with the function of side points, and supports various processes such as single-step operation, integral machining, simulated operation and automatic circular

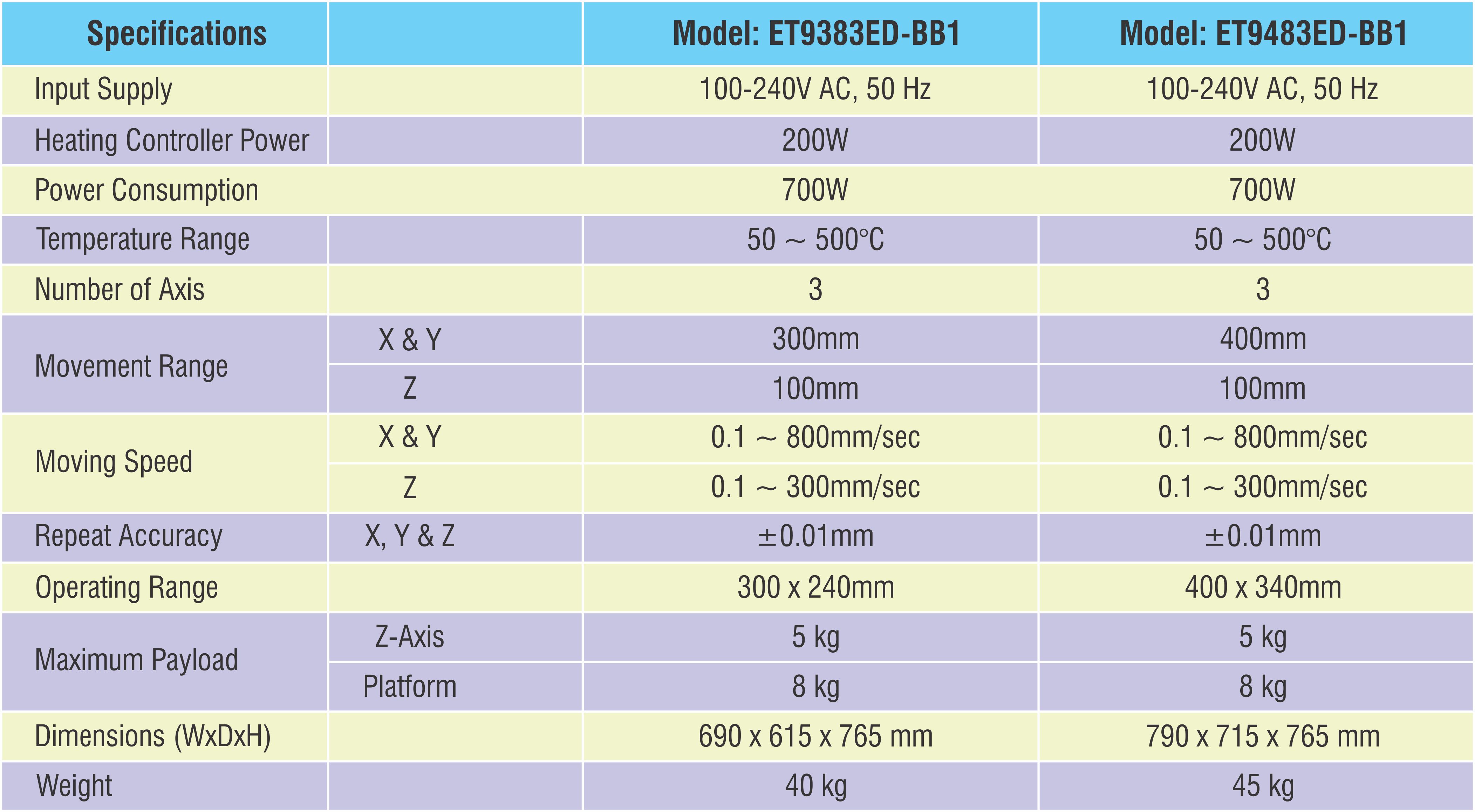

Specifications for ET9383E-BB1 and ET9483E-BB1

- 3-Axis Soldering Robot

- Hand-held Teaching Pendant

- Soldering & Wire Feeding Controller

- Soldering & Wire Feeding Head

- 911G Series Soldering Tip

- Soldering Tip Cleaning System

![]()

4-Axis Highly Reliable Soldering Robot

Model: ET9384E-BB1 / ET9484E-BB1

The 4-Axis Soldering Robot is a type of industrial robot that is designed for precision soldering applications. It typically consists of 4-Axis of movement, including X, Y, Z, and a rotary axis R. This additional rotary R-Axis allows more flexibility and range of motion in the soldering process, which can be useful for working on complex or irregularly shaped objects. Some common features of 4-Axis Soldering Robots include high precision and accuracy, fast cycle times and the ability to program and automate soldering processes. They may also be equipped with various sensors and feedback systems to ensure consistent and reliable soldering results. Soldering Robot increase production with less hand and ensures consistent soldering quality for each joint.

Overall, 4-Axis Soldering Robots is a valuable tool for manufacturers and other industrial users who require high-quality, high-volume soldering capabilities. These Soldering Robots helps to increase productivity, reduce labor costs, and improve overall product quality and consistency.

- Motion Platform

E-Series Soldering Platform is of high speed & high accuracy with low noise, closed-loop control of Y-axis, no lost steps, strong load capacity, easy maintenance, rich I/O interfaces, support MES to read local data and expand operation use, two-hand start (optional), ESD safe - Heating Controller

Heating Controller uses high frequency eddy current heating for stable and reliable temperature, fast thermal recovery, RS-485 interface for real-time monitoring and to set parameters like temperature, solder feeding etc, alarm for abnormal temperature and solder shortage etc. - Soldering Pencil

High Power Soldering Pencil has front temperature sensor for quick sensing of solder joint temperature fluctuation and rapid thermal recovery. - Solder Feeder

Small size and high precision, controlled by precision stepper motor, the minimum solder feeding length can reach 0.1mm, solder shortage and block alarm function available. - Teaching Pendant

Teaching Pendant, supports array and group functions, with the function of side points, and supports various processes such as single-step operation, integral machining, simulated operation and automatic circular

Specifications for ET9384E-BB1 and ET9484E-BB1

- 4-Axis Soldering Robot

- Hand-held Teaching Pendant

- Soldering & Wire Feeding Controller

- Soldering & Wire Feeding Head

- 911G Series Soldering Tip

- Soldering Tip Cleaning System

![]()

Dual Platform 3-Axis & 4-Axis Highly Reliable Soldering Robot

Model: ET9583EYA-BB1 / ET9584EYA-BB1

The 4-Axis Dual Platform Soldering Robot is a type of industrial robot that is designed for precision soldering applications. It typically consists of 4-Axis of movement, including X, Y, Z, and a rotary axis R. This additional rotary R-Axis allows more flexibility and range of motion in the soldering process, which can be useful for working on complex or irregularly shaped objects. Some common features of 4-Axis Soldering Robots include high precision and accuracy, fast cycle times and the ability to program and automate soldering processes. They may also be equipped with various sensors and feedback systems to ensure consistent and reliable soldering results. Soldering Robot increase production with less hand and ensures consistent soldering quality for each joint.

Overall, 4-Axis Soldering Robots is a valuable tool for manufacturers and other industrial users who require high-quality, high-volume soldering capabilities. These Soldering Robots helps to increase productivity, reduce labor costs, and improve overall product quality and consistency.

- Motion Platform

E-Series Soldering Platform is of high speed & high accuracy with low noise, closed-loop control of Y-axis, no lost steps, strong load capacity, easy maintenance, rich I/O interfaces, support MES to read local data and expand operation use, two-hand start (optional), ESD safe - Heating Controller

Heating Controller uses high frequency eddy current heating for stable and reliable temperature, fast thermal recovery, RS-485 interface for real-time monitoring and to set parameters like temperature, solder feeding etc, alarm for abnormal temperature and solder shortage etc. - Soldering Pencil

High Power Soldering Pencil has front temperature sensor for quick sensing of solder joint temperature fluctuation and rapid thermal recovery. - Solder Feeder

Small size and high precision, controlled by precision stepper motor, the minimum solder feeding length can reach 0.1mm, solder shortage and block alarm function available. - Teaching Pendant

Teaching Pendant, supports array and group functions, with the function of side points, and supports various processes such as single-step operation, integral machining, simulated operation and automatic circular

Specifications for ET9583EYA-BB1 and ET9584E-BB1

- 3-Axis/4-Axis Soldering Robot

- Hand-held Teaching Pendant

- Soldering & Wire Feeding Controller

- Soldering & Wire Feeding Head

- 911G Series Soldering Tip

- Soldering Tip Cleaning System

![]()

Dual Head 3-Axis Highly Reliable Soldering Robot

Model: ET9383ED-BB1 / ET9483ED-BB1

The Dual Head 3-Axis Soldering Robot is a type of industrial robot that is designed for precision soldering applications. It typically consists of 3-Axis of movement, including X, Y, Z. Some common features of 3-Axis Soldering Robots include high precision and accuracy, fast cycle times and the ability to program and automate soldering processes. Dual Head Soldering Robot increase production with less hand and ensures consistent soldering quality for each joint. It can solder two identical jobs simultaneously. These Soldering Robots helps to increase productivity, reduce labor costs, and improve overall product quality and consistency.

- Motion Platform

E-Series Soldering Platform is of high speed & high accuracy with low noise, closed-loop control of Y-axis, no lost steps, strong load capacity, easy maintenance, rich I/O interfaces, support MES to read local data and expand operation use, two-hand start (optional), ESD safe - Heating Controller

Heating Controller uses high frequency eddy current heating for stable and reliable temperature, fast thermal recovery, RS-485 interface for real-time monitoring and to set parameters like temperature, solder feeding etc, alarm for abnormal temperature and solder shortage etc. - Soldering Pencil

High Power Soldering Pencil has front temperature sensor for quick sensing of solder joint temperature fluctuation and rapid thermal recovery. - Solder Feeder

Small size and high precision, controlled by precision stepper motor, the minimum solder feeding length can reach 0.1mm, solder shortage and block alarm function available. - Teaching Pendant

Teaching Pendant, supports array and group functions, with the function of side points, and supports various processes such as single-step operation, integral machining, simulated operation and automatic circular

- 3-Axis Dual Head Soldering Robot

- Hand-held Teaching Pendant

- 2xSoldering & Wire Feeding Controller

- 2xSoldering & Wire Feeding Head

- 911G Series Soldering Tip

- 2xSoldering Tip Cleaning System

![]()

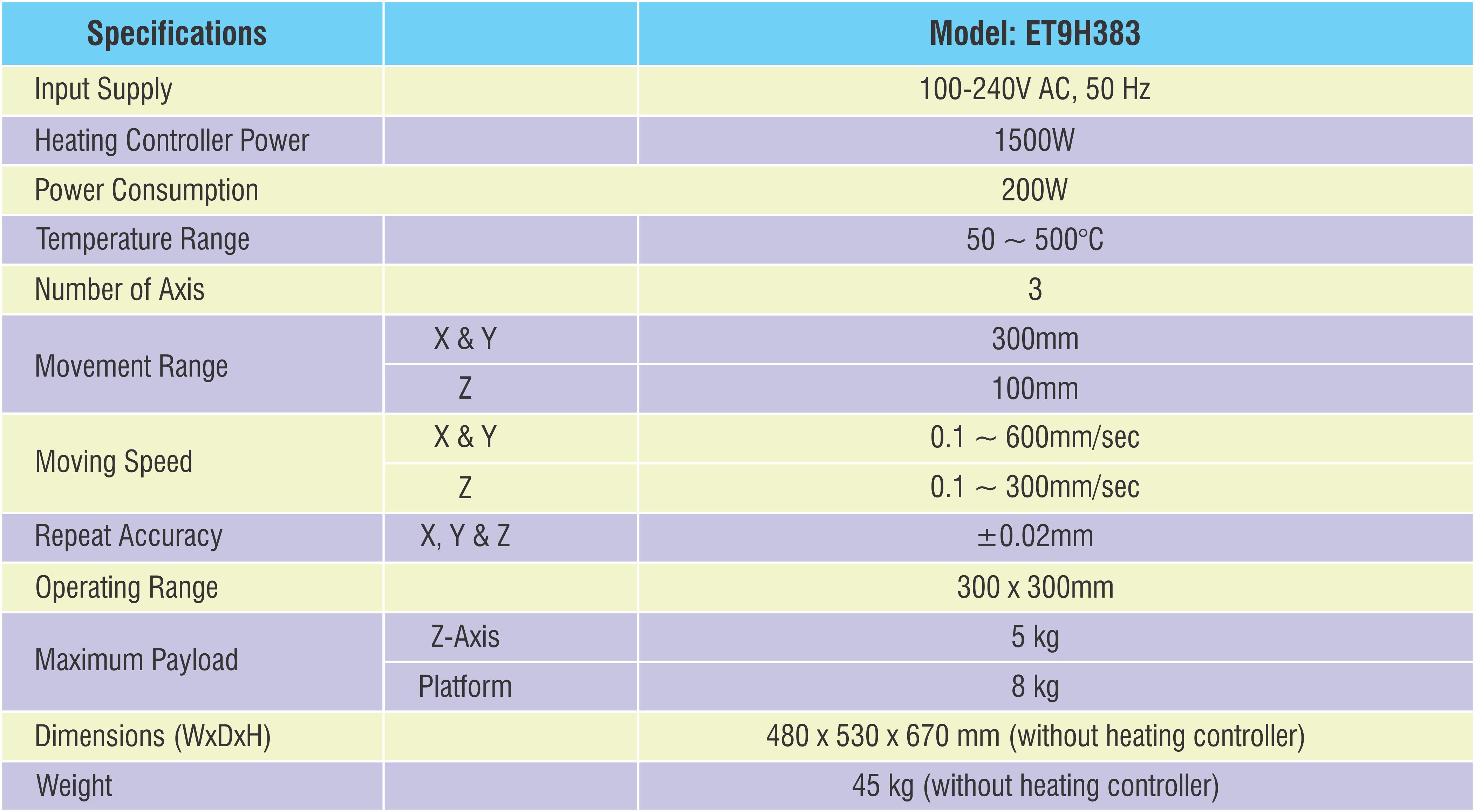

Highly Reliable Robotic Hot Bar Soldering Machine

Model: ET9H383

This Hot Bar Robotic Soldering Machine is used for soldering multiple contacts of flexible ribbons like in LCD Panels.

Motion Platform

Y-Axis controlled by closed-loop motor, with strong load capacity and accurate speed control,double-rail for X/Y axis, precise moving, multiple groups of soldering process parameters selectable, can read parameters through MES and can be started with both hands (single or two hand optional), which is safe & reliable.

Heating Controller

Intelligent temperature control system, accurate and stable temperature, closed-loop temperature control, RS485 communication function which can communication with PC/PLC, alarm of abnormal temperature available.

Pressure Assembly

Closed-loop pressure control with abnormal pressure alarm

Teaching Pendant

9011D Teaching Pendant, supports array and group functions, easily cope with mold deviation and deviation of tip replacement, can support multiple processing modes such as single-step operation, integral processing, simulated operation, and cyclic automatic processing.

- Desktop Hotbar Soldering Robot

- Hand-held Teaching Pendant

- Pressure Assembly

- Operating Manual

![]()